Narrowboat Rhiannon: Water Tank Lining

The owner of the narrowboat Rhiannon contacted us for technical advice and for the supply of materials for the lining of a corroded – rusty steel drinking water tank on his narrowboat.

The Client

The owner of a narrowboat, Rhiannon, approached us for technical advice and materials in order to refurbish the corroded and rusted liner of the vessel’s steel drinking water tank.

“If possible we prefer to avoid using a bladder system”, because we don’t want run the risk of moisture being trapped between the bladder and the steel hull.

His genuine concernes of the steel corroding behind the bladder and it being left undetected, is not an issue with our coating system.

Ideally, our client wanted to be able to carry out the work himself.”

Challenges

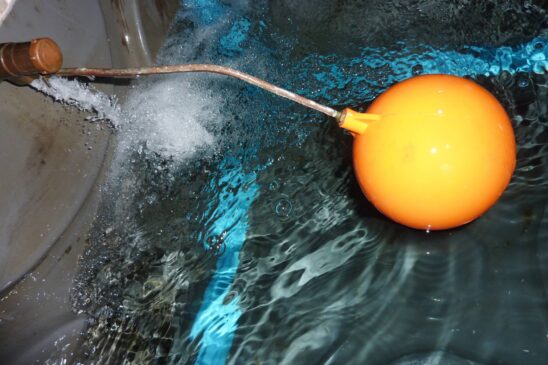

The project presented a number of challenges. The narrowboat had an integrated water tank that was built into the structure of the boat and could not be removed. This resulted in a limited working space.

It was likely that the narrowboat would remain in the water while the work was carried out, so the surface of the steel would be cold and potentially damp. The tank was previously unlined, and significant corrosion was visible. The client wanted to carry out the repairs and installation work himself, so he only required materials and technical advice from us.

Solution

We have developed an advanced water tank lining system that is ideal for use on narrowboats. Our specification for this project was to supply the materials, which comprised an anti-corrosion and damp-tolerant resin primer coat as well as damp-tolerant and drinking water-approved intermediate and topcoats. These materials are all based on epoxy resin technology, which offers multiple advantages.

The drinking water-approved lining system is solvent-free, low-odour, easy to apply and highly durable. Although the use of these materials necessitates some practical and technical ability, we provide detailed instructions and guide notes based on our extensive experience. We also offer free technical telephone support.

The materials are impermeable and offer excellent corrosion resistance. They can be used on tanks that have been previously lined with bitumen, and they prevent the bitumen from bleeding through and contaminating the water. The topcoat’s glass flake-reinforced technology creates an impenetrable surface. It is ideal for use in confined spaces due to its ease of application.

Results

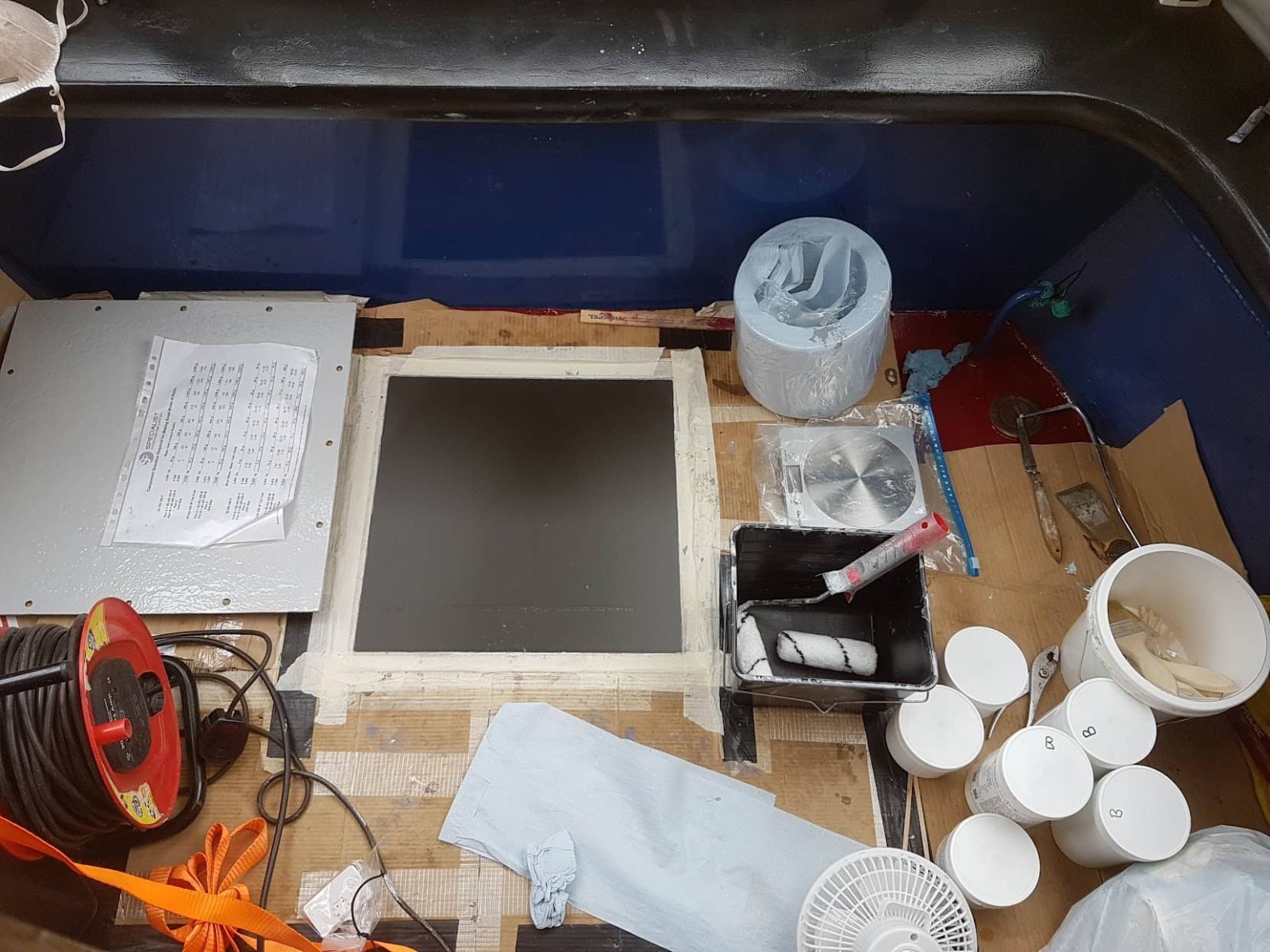

Throughout this project, we provided step-by-step technical advice regarding tools and equipment, surface preparation, and the mixing and application of materials. We also assisted in resolving issues specific to this narrowboat.

The potable water tank was integrated into the hull, our system provided a cost-effective solution, with correct surface preparation/ application our system will provide years of maintenance-free use.

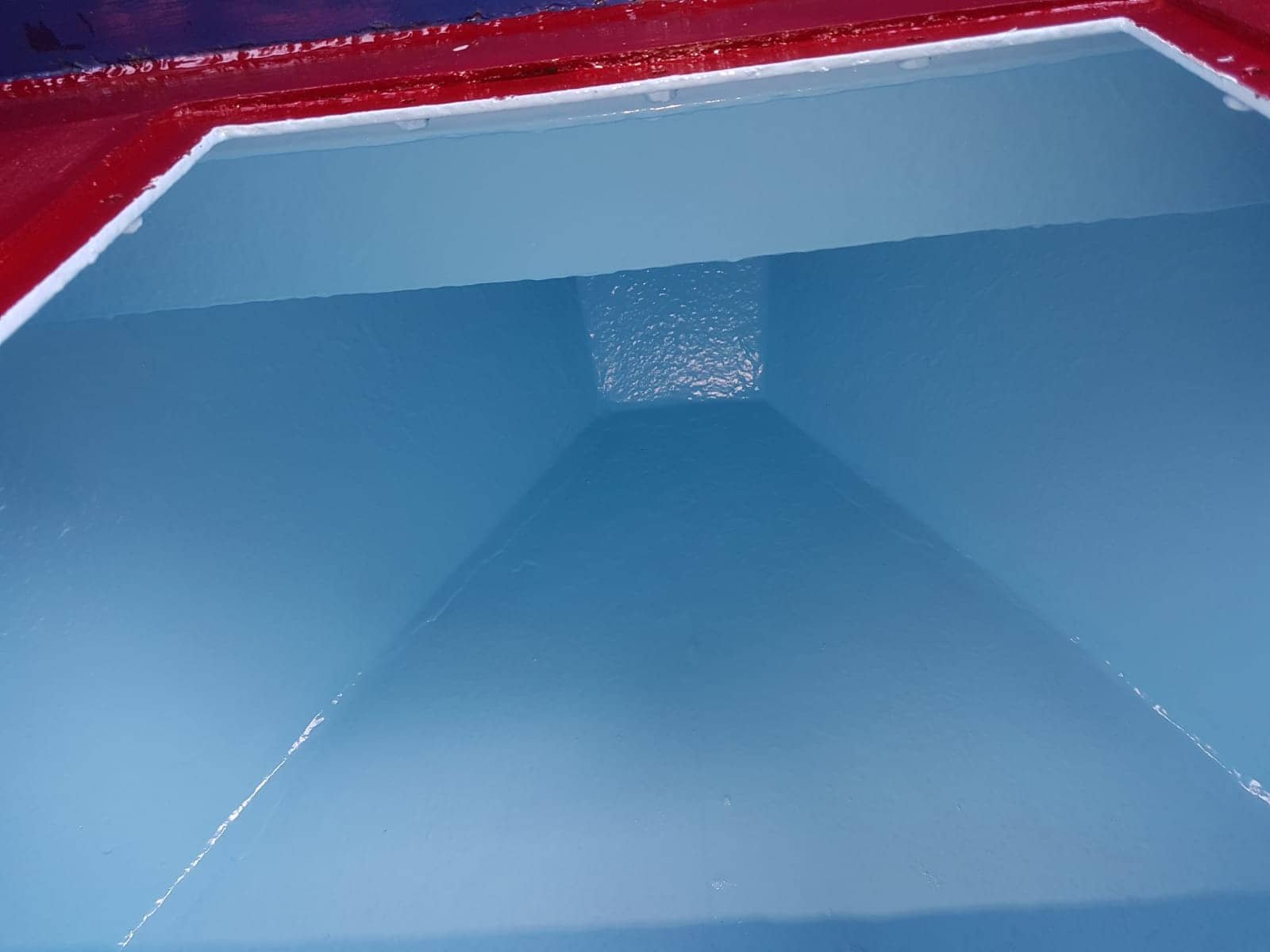

Narrowboat Water Tank Lining Before and After Treatment

Support

We provided detailed technical advice regarding surface preparation, mixing and application of the materials and also help pages for getting around troubleshooting problems and if required the tools and equipment to carry out the work too.

Unlike other companies, we are happy to give telephone support, even out of hours and at weekends, to help with general guidance, technical questions or simply moral support. We would rather talk you through something, even if it is confirming that everything is ok, rather than you worrying about something that could be easily fixed with a quick phone call.

With correct surface preparation, this system will give narrowboat owners many years of maintenance-free use.